Sevices

PVC Pipes and Fittings

APC PVC pipes and fittings are synonymous with superior quality, robust strength, and unequalled durability. PVC stands for polyvinyl chloride, one of the most widely used polymers in the world. Due to its versatile nature, PVC is used extensively across a broad range of industrial, technical, and everyday applications. PVC pipes are manufactured using PVC resin as a raw material through an extrusion process.Pipes are made from high grade in-house manufactured PVC resin and advanced extrusion machines and subjected to numerous quality tests to ensure extreme weather withstanding capacity and perfect for everyday usage. A reputation we have earned by being tough on ourselves by keeping tight. checks on raw materials, processes, compositions, and thicknesses. PVC pipes are mainly categorised into Unplasticized PVC (UPVC) & Chlorinated PVC (CPVC) pipes.

PVC Pipes and Fittings :

PVC Selfit Pipes

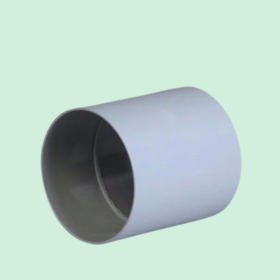

Coupler

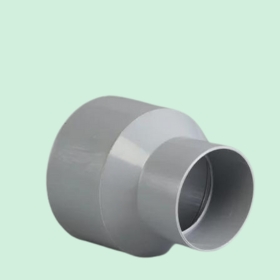

Reducer

Tail Piece

Elbow

Elbow Threaded

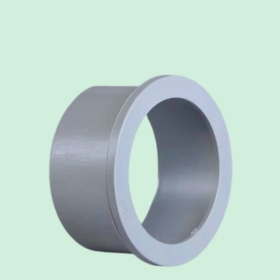

Reducing Bush

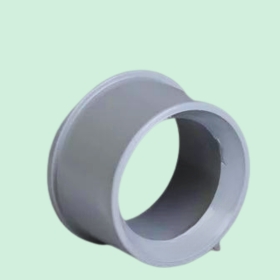

Flange

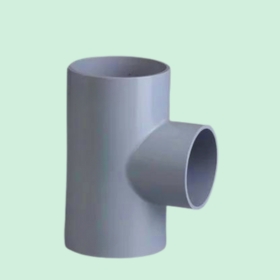

TEE

Reducing TEE

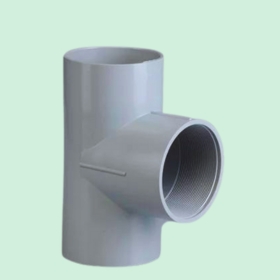

TEE Threaded

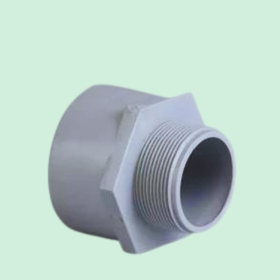

M.T.A

Y TEE

Reducing MTA

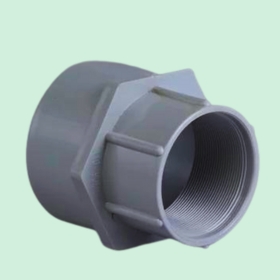

F.T.A

Reducing FTA

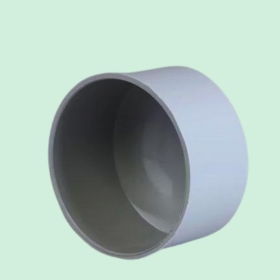

End Cap Plain

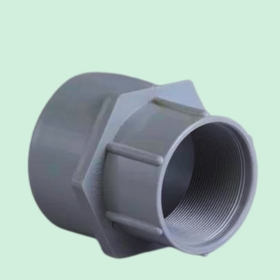

End Cap Threaded

Service Saddle

Reducing FTA

Features & Benefits

Meets global standards for housing and industry applications.

Lead Free.

UV Stabilized, ensuring protection from direct sunlight

Corrosion-free and chemical resistant.

Ideal for potable water transportation.